Why The Box and Systems Need to Play Nicely Together

My perspective comes from being at A1DesignBuild almost two years now, as a designer/architect. I brought to the table some good experience in energy and building enclosure engineering in the commercial world. Being a part of this cooperative’s continual development of high-performance homes has been the most exciting, geeky experience yet.

When the components of a building’s enclosure (aka The Box) are optimized to limit energy losses and mechanical systems are integrated in design and construction, energy system can be engineered to be smaller.

This is how we do it: we design an air-tight, super-insulated box, do energy modeling to determine the optimal size/power of the air-handling system — which is fundamentally a filtered fan. Then, we build it.

The airtight box

In earlier blog posts, we wrote about a home’s air/vapor control, insulation, and fresh air systems – and how they work together to provide comfort and performance. In fact, our design and construction team have been implementing high performance enclosure systems for some time now. If these systems are not designed and installed with a plan, you’ll lose lots of energy out of the cracks and air gaps in your enclosure – we air seal with industry-proven products like Siga brand house wraps, flashings and tapes

Super-insulated

And while insulation slows losses, energy does travels through the insulation layers. We counter these losses with insulating systems that exceed code and can be defined as high performing. The higher the R-value, the better an insulator. We are now using hearty thermal system components such as:

Continuous insulation – rigid boards that are installed just beneath siding to break the connection between energy-extracting framing and the outside temperatures. We can more than double the insulation value of walls by adding this second layer of insulation to the outside of wall framing.

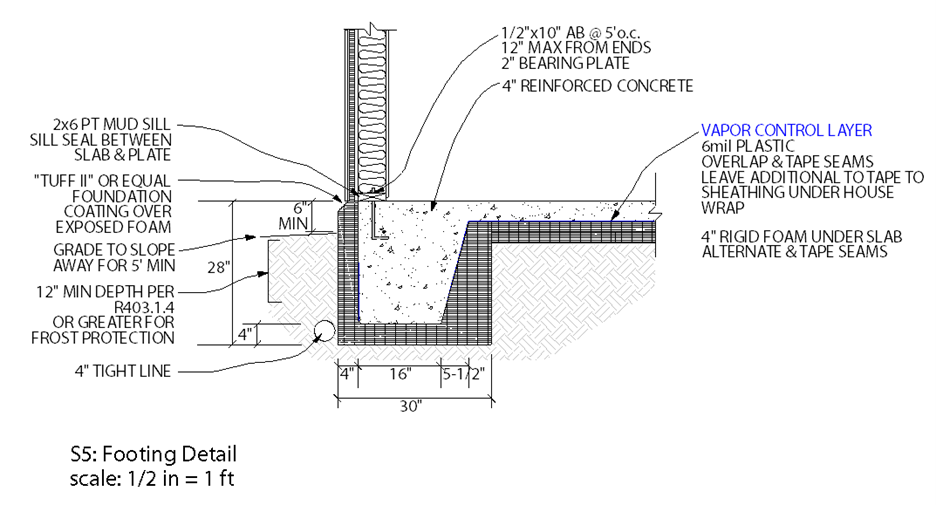

Cutting edge foundation forms - developed in-house to meet energy demands that are also regionally sourced to reduce carbon footprint (and shipping costs) – far exceeding energy code requirements and approaching the highest standards currently being used. These forms allow for insulation underneath the concrete, keeping the heat on the warm side of the house and limiting heat loss through the footings.

Windows that have an R-value more than R-6, unheard of just a few years ago but now available here. Code standard is usually around R-3.5.

Structurally Insulated Panels (SIPS) – sandwich panels made by locally-produced by Premier Building Systems of a core of rigid insulation between plywood sheets These panels limit the amount of framing and maximize performance of the insulation.

Foam form prototypes for footings developed by A1DesignBuild

Foam extrusions allow placement of concrete footings into a fully insulated, below-grade system that provides continual unbroken insulation to the wall systems, minimizing heat loss.

Integrated Air Handling System: Energy Modeling

There’s another type of collaboration that’s going on, though – the enclosure can enhance the fresh air and heating / cooling systems. And it’s all predictable and calculable and geeky.

Because of the low air leakage and high insulation of our enclosures, our design team is now able to use Passive House energy modeling software and other tools to accurately predict heating and cooling energy demands on a consistent basis. The software takes into consideration the The Box components mentioned above, along with several other factors such as building orientation and site conditions.

The resulting lower energy demands from our high-performing air and thermal control layers mean we could specify heating and cooling systems at around 15 to 17 BTUh/square foot of living space – half the size of a standard code compliant home or what the heating industry might consider a normal sized system for a house.

A Manual J Energy Calculation Report

Our preferred heating and cooling systems are electric air source heat pumps. According to the U.S. Department of Energy, a properly installed air-source heat pump can deliver up to three times more heat energy to a home than the electrical energy it consumes – it’s like grabbing free energy from the outside air.

With the governor’s Clean Energy Transformation Act, which commits Washington to an electricity supply free of greenhouse gas emissions by 2045, electricity in this area is now the go-to green source over fossil fuels.

All of this means that when The Box and heating/cooling systems are integrated in design and construction, energy systems can be engineered to use far less energy. How wonderful – for our clients, our community, and our world.